3D-Pprinted Personalized Dashboard Panels

The Rise of 3D-Printed Personalized Dashboard Panels

In recent years, the automotive and tech industries have witnessed a significant shift towards customization and personalization. One of the most exciting developments in this space is the advent of 3D-printed personalized dashboard panels. These panels are not only functional but also serve as a canvas for individual expression, allowing users to tailor their vehicle interiors to their unique tastes and preferences. 3D printing technology's incorporation has made it possible to produce complicated patterns and detailed features hitherto unreachable using conventional manufacturing techniques.

How 3D Printing Technology is Revolutionizing Dashboard Design

3D printing, also known as additive manufacturing, has emerged as a game-changer in various industries, and automotive design is no exception. Unlike traditional manufacturing processes that involve cutting, molding, or assembling parts, 3D printing builds objects layer by layer from a digital model. This method allows for unparalleled precision and flexibility in design. For dashboard panels, this means that manufacturers can create bespoke designs that cater to the specific needs and preferences of individual customers. The technology also enables rapid prototyping, reducing the time and cost associated with developing new designs.

The Benefits of Personalized Dashboard Panels

Personalized dashboard panels offer a range of benefits that go beyond aesthetics. For one, they enhance the overall user experience by allowing drivers to interact with a dashboard that reflects their personality and style. Additionally, these panels can be designed to improve functionality, with custom layouts that make it easier to access controls and information. From a practical standpoint, 3D-printed panels are often lighter and more durable than their traditionally manufactured counterparts, contributing to better fuel efficiency and longevity. Furthermore, the ability to update or replace panels easily means that users can keep their vehicles looking fresh and modern without the need for extensive modifications.

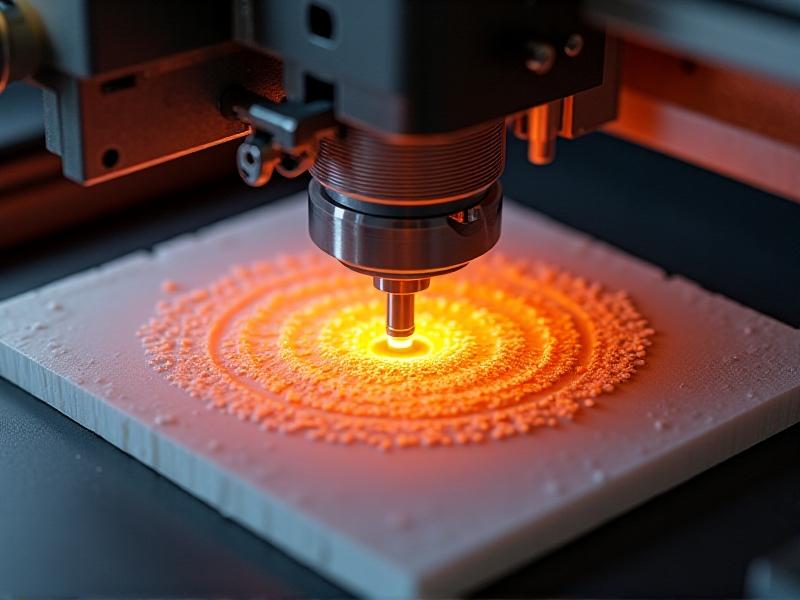

Materials and Techniques in 3D-Printed Dashboard Panels

The choice of materials plays a crucial role in the quality and performance of 3D-printed dashboard panels. Common materials include thermoplastics like ABS and PLA, which are known for their strength and flexibility. More advanced options, such as carbon fiber-reinforced polymers, offer even greater durability and lightweight properties. The printing techniques used also vary, with Fused Deposition Modeling (FDM) being one of the most popular methods. Other techniques, such as Selective Laser Sintering (SLS) and Stereolithography (SLA), provide higher resolution and finer details, making them ideal for complex designs. The combination of these materials and techniques allows for the creation of panels that are not only visually appealing but also highly functional.

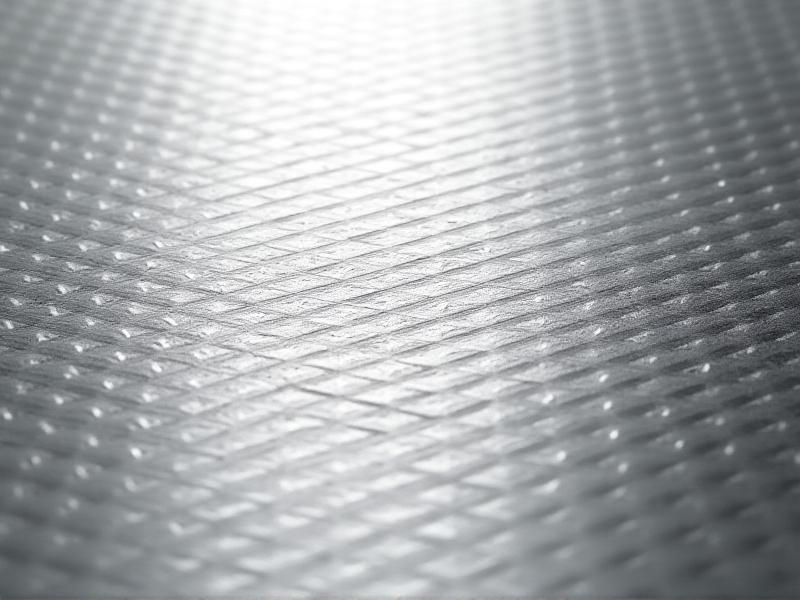

Customization Options: From Aesthetics to Functionality

One of the most appealing aspects of 3D-printed personalized dashboard panels is the wide range of customization options available. Users can choose from a variety of colors, textures, and finishes to create a look that matches their personal style. Beyond aesthetics, customization can also extend to functionality. For example, panels can be designed with specific layouts that cater to the driver's preferences, such as the placement of controls or the integration of additional features like wireless charging pads or extra storage compartments. Some manufacturers even offer the option to incorporate personal logos or artwork into the design, making the dashboard truly one-of-a-kind.

The Future of 3D-Printed Dashboard Panels in the Automotive Industry

As 3D printing technology continues to evolve, its impact on the automotive industry is expected to grow significantly. In the future, we can anticipate even more advanced materials and techniques that will further enhance the quality and functionality of 3D-printed dashboard panels. Additionally, the rise of electric and autonomous vehicles presents new opportunities for innovation in dashboard design. With fewer traditional controls needed, there is greater potential for creative and user-centric layouts. Moreover, the ability to produce panels on-demand could lead to a shift in how vehicles are manufactured and sold, with a greater emphasis on personalization and user experience. The future of 3D-printed dashboard panels is not just about technology; it's about redefining the relationship between drivers and their vehicles.