Automotive-Grade Hydro Dip Patterns

The Rise of Automotive-Grade Hydro Dip Patterns

Hydro dipping, also known as water transfer printing, has revolutionized the automotive customization industry. This technique allows for intricate and vibrant patterns to be applied to various surfaces, including car parts. Automotive-grade hydro dip patterns have gained popularity due to their durability, versatility, and aesthetic appeal. From carbon fiber textures to camouflage designs, hydro dipping offers endless possibilities for car enthusiasts looking to personalize their vehicles.

How Hydro Dipping Works: The Science Behind the Art

Hydro dipping involves a meticulous process that begins with the preparation of the surface to be coated. The item is initially painted with a base coat, cleaned, and primed. A film with the desired pattern is then placed on the surface of water in a dipping tank. Activator chemicals are sprayed onto the film, causing it to dissolve and become a liquid layer. The item is carefully dipped into the water, allowing the pattern to adhere to its surface. The final step involves rinsing and sealing the item to ensure the design is durable and long-lasting.

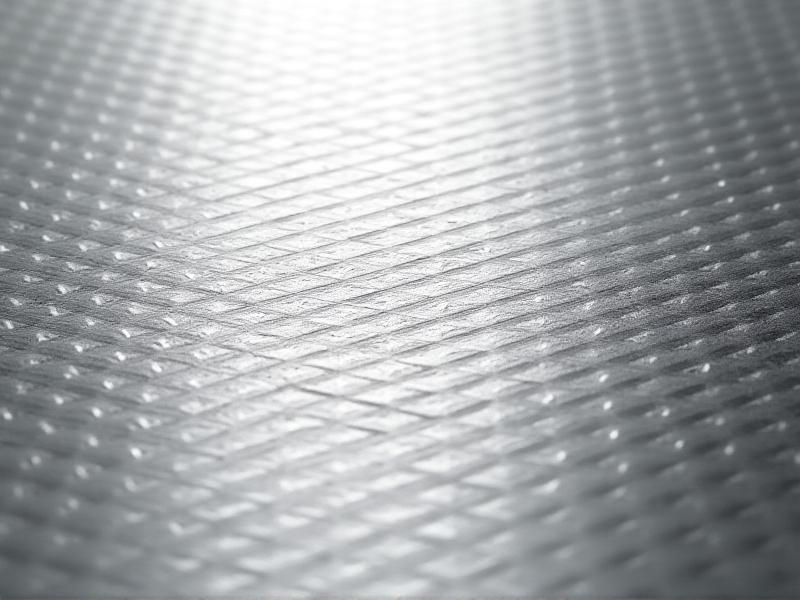

Popular Hydro Dip Patterns for Automotive Use

When it comes to automotive hydro dipping, certain patterns have become particularly popular. Carbon fiber patterns are a favorite for their sleek, modern look, often used on hoods, dashboards, and trim. Camouflage designs offer a rugged, off-road aesthetic, perfect for SUVs and trucks. Wood grain patterns provide a classic, luxurious feel, ideal for interior accents. Other popular choices include geometric designs, animal prints, and custom graphics that reflect the owner’s personality and style.

Benefits of Automotive-Grade Hydro Dip Patterns

Automotive-grade hydro dip patterns offer numerous advantages over traditional paint jobs. The procedure is affordable and provides for premium customisation without the expensive cost. Hydro dipping is also highly durable, resistant to chipping, fading, and wear. Its adaptability for various automobile components comes from the fact that it can be used on a broad spectrum of materials, including plastic, metal, and fiberglass. Additionally, hydro dipping provides a seamless finish, with patterns that wrap around complex shapes and contours without visible seams or overlaps.

Customization and Personalization: Making Your Car Unique

One of the most appealing aspects of hydro dipping is the ability to create truly unique designs. Custom patterns can be tailored to reflect the owner’s interests, hobbies, or brand identity. Whether it’s a sports team logo, a favorite animal, or a one-of-a-kind abstract design, hydro dipping allows for endless creativity. This level of personalization ensures that no two vehicles are exactly alike, making each car a true reflection of its owner’s individuality.

Maintenance and Care for Hydro Dipped Surfaces

To keep hydro dipped surfaces looking their best, proper maintenance is essential. Regular cleaning with mild soap and water helps to remove dirt and grime without damaging the finish. Avoid using abrasive cleaners or tools that could scratch the surface. Applying a protective wax or sealant can help to preserve the pattern and enhance its durability. With proper care, hydro dipped car parts can maintain their vibrant appearance for years to come.

The Future of Hydro Dipping in the Automotive Industry

As technology continues to advance, the possibilities for hydro dipping in the automotive industry are expanding. Innovations in film production and application techniques are leading to even more intricate and durable designs. Additionally, the growing demand for personalized and unique vehicles is driving the popularity of hydro dipping. With its combination of affordability, durability, and creativity, hydro dipping is poised to remain a key player in automotive customization for years to come.