Laser-Etched Aluminum Side Panels

The Rise of Laser-Etched Aluminum Side Panels in Modern Design

In recent years, laser-etched aluminum side panels have emerged as a popular choice in various industries, from consumer electronics to automotive design. The precision and versatility of laser etching technology allow for intricate designs and patterns that were previously unattainable. This section explores the growing trend of using laser-etched aluminum side panels and how they are transforming the aesthetics and functionality of products.

The Technology Behind Laser Etching on Aluminum

Laser etching is a process that uses high-powered lasers to remove material from the surface of aluminum, creating detailed and permanent designs. This section delves into the technical aspects of laser etching, including the types of lasers used, the process of etching, and the benefits of this technology over traditional methods. We’ll also discuss how advancements in laser technology have made it more accessible and cost-effective for manufacturers.

Applications of Laser-Etched Aluminum Side Panels

Laser-etched aluminum side panels are used in a wide range of applications, from high-end electronics to luxury vehicles. This part looks at the several sectors—including consumer electronics, automobile, aerospace, and architectural design—that gain from this technology. We’ll highlight specific examples of products that feature laser-etched aluminum panels and discuss how they enhance both the form and function of these items.

Design Possibilities with Laser-Etched Aluminum

One of the most exciting aspects of laser-etched aluminum side panels is the endless design possibilities they offer. This section explores the creative potential of laser etching, from custom logos and branding to intricate artistic patterns. We’ll discuss how designers can use this technology to create unique and personalized products that stand out in the market. Additionally, we’ll touch on the importance of design software and how it integrates with laser etching technology.

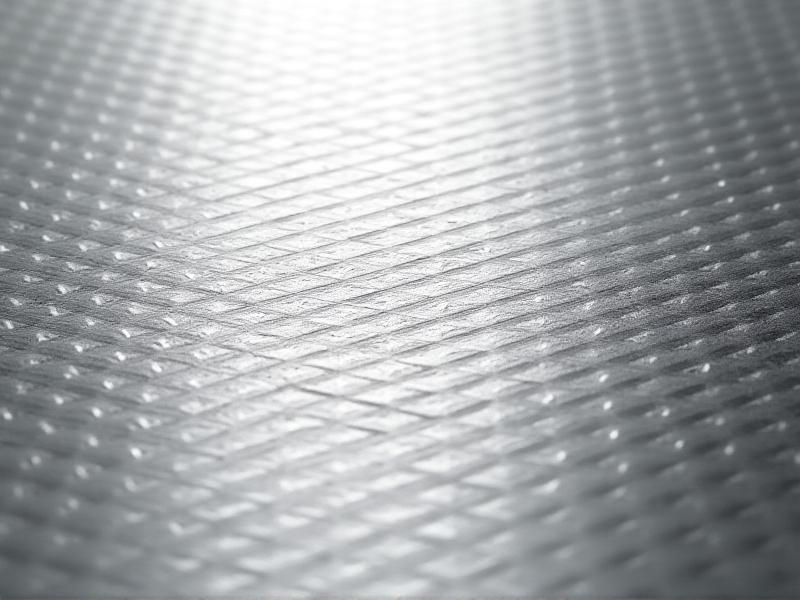

Durability and Performance of Laser-Etched Aluminum

Beyond their aesthetic appeal, laser-etched aluminum side panels are known for their durability and performance. This section examines the material properties of aluminum that make it ideal for laser etching, including its resistance to corrosion, strength, and lightweight nature. We’ll also discuss how laser etching enhances the durability of aluminum panels by creating a protective layer that resists wear and tear over time.

Environmental Benefits of Laser-Etched Aluminum

As sustainability becomes a growing concern, laser-etched aluminum side panels offer an environmentally friendly alternative to other materials and processes. This section explores the eco-friendly aspects of laser etching, including the reduction of waste, energy efficiency, and the recyclability of aluminum. We’ll also discuss how manufacturers can adopt sustainable practices when using laser etching technology.

Challenges and Considerations in Laser Etching Aluminum

While laser etching offers many advantages, there are also challenges and considerations that manufacturers must address. This section covers potential issues such as the cost of equipment, the learning curve for operators, and the limitations of design complexity. We’ll also discuss how to overcome these challenges and ensure high-quality results when working with laser-etched aluminum side panels.

Future Trends in Laser-Etched Aluminum Side Panels

As technology continues to evolve, so too will the applications and capabilities of laser-etched aluminum side panels. This section looks ahead to future trends, including the integration of smart technologies, the use of AI in design, and the potential for new materials and finishes. We’ll also explore how these advancements could shape the future of product design and manufacturing.

How to Choose the Right Laser-Etched Aluminum Panel for Your Project

Selecting the right laser-etched aluminum panel for your project involves considering various factors such as design, durability, and cost. This section provides practical advice on how to choose the best panel for your needs, including tips on working with manufacturers, understanding material specifications, and ensuring compatibility with your design goals. We’ll also discuss the importance of prototyping and testing before finalizing your choice.

Case Studies: Successful Use of Laser-Etched Aluminum Side Panels

To illustrate the impact of laser-etched aluminum side panels, this section presents case studies of successful projects across different industries. We’ll explore how companies have used laser etching to enhance their products, improve brand recognition, and achieve their design objectives. Each case study will provide insights into the decision-making process, challenges faced, and the outcomes achieved.

Maintenance and Care for Laser-Etched Aluminum Side Panels

Proper maintenance and care are essential to ensure the longevity and appearance of laser-etched aluminum side panels. This section offers practical tips on how to clean, protect, and maintain these panels, including recommended cleaning products and techniques. We’ll also discuss how to address common issues such as scratches or fading, and how to preserve the intricate designs created through laser etching.