Thermal Insulation for Battery Compartments

Understanding the Importance of Thermal Insulation in Battery Compartments

Thermal insulation plays a critical role in the design and functionality of battery compartments, particularly in electric vehicles (EVs) and renewable energy storage systems. Batteries, especially lithium-ion variants, are sensitive to temperature fluctuations. Excessive heat can lead to thermal runaway, a dangerous condition where the battery overheats and potentially catches fire. Conversely, extremely low temperatures can reduce battery efficiency and lifespan. Effective thermal insulation ensures that batteries operate within their optimal temperature range, enhancing performance, safety, and longevity.

From sweltering summers to cold winters, modern battery compartments are designed to resist severe weather conditions. Insulation materials must not only prevent heat transfer but also resist moisture, vibrations, and mechanical stress. As the demand for EVs and renewable energy solutions grows, the need for advanced thermal insulation technologies becomes increasingly paramount. This section delves into the science behind thermal insulation and its significance in battery compartments, setting the stage for a deeper exploration of materials, design strategies, and real-world applications.

Materials Used in Thermal Insulation for Battery Compartments

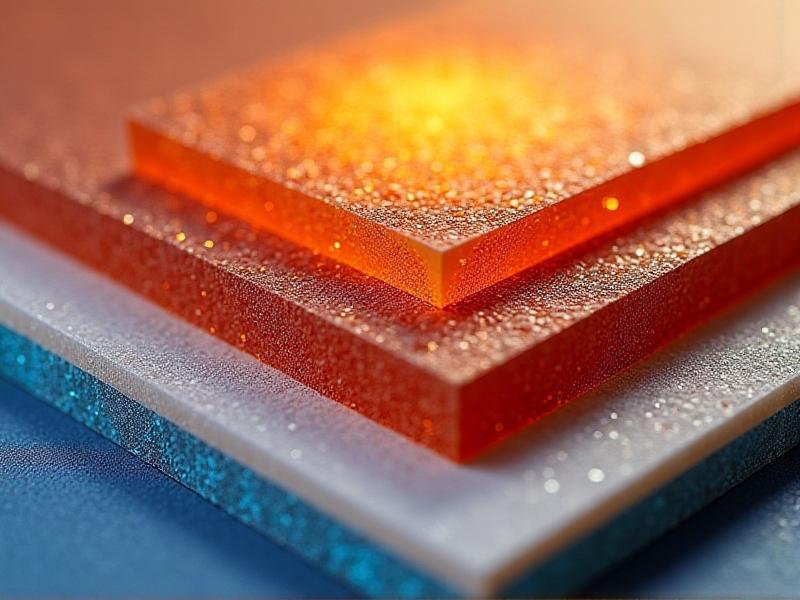

The choice of insulation material is pivotal in ensuring the effectiveness of thermal management in battery compartments. Common materials include ceramic fibers, aerogels, phase change materials (PCMs), and foams. Ceramic fibers are lightweight and possess excellent thermal resistance, making them ideal for high-temperature applications. Aerogels, often referred to as "frozen smoke," are highly porous materials with low thermal conductivity, offering superior insulation in minimal space.

Phase change materials absorb and release thermal energy during phase transitions, helping to regulate temperature spikes. Foams, such as polyurethane and polystyrene, provide both insulation and structural support. Each material has its unique properties, advantages, and limitations, and the selection often depends on factors like cost, weight, and specific application requirements. This section explores these materials in detail, highlighting their roles in maintaining battery efficiency and safety.

Design Strategies for Effective Thermal Insulation

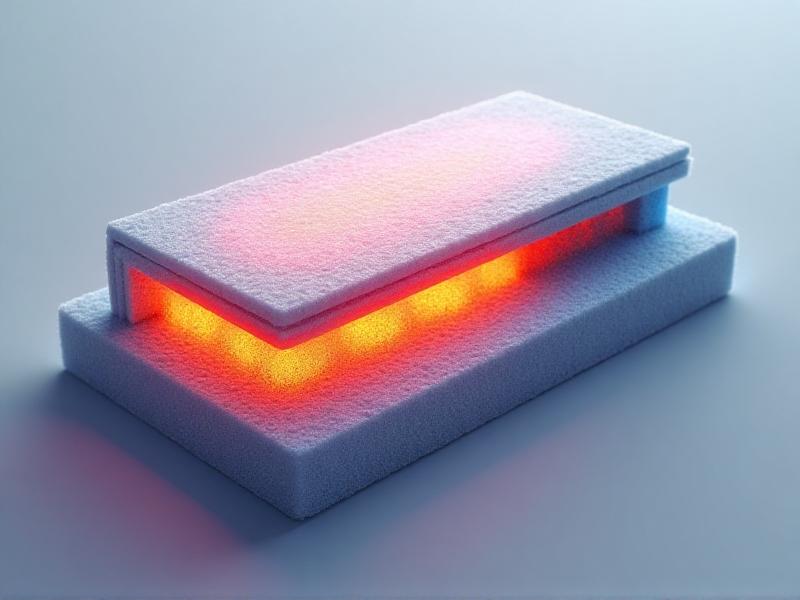

Designing an effective thermal insulation system for battery compartments involves more than just selecting the right materials. Engineers must consider factors such as heat dissipation, airflow, and the integration of cooling systems. Passive insulation relies on materials with low thermal conductivity to minimize heat transfer, while active insulation incorporates cooling mechanisms like liquid cooling or thermoelectric devices.

The geometry of the battery compartment also plays a crucial role. Compact designs with minimal air gaps reduce heat transfer, while modular designs allow for easier maintenance and replacement of insulation components. Additionally, computational modeling and simulation tools are used to optimize insulation performance under various conditions. This section examines the design principles and strategies that ensure thermal insulation systems are both efficient and practical.

Challenges in Thermal Insulation for Battery Compartments

Despite advancements in materials and design, thermal insulation for battery compartments faces several challenges. One major issue is balancing insulation with weight, as excessive insulation can add bulk and reduce the overall efficiency of EVs. Another challenge is ensuring durability, as insulation materials must withstand vibrations, impacts, and environmental stressors over time.

Cost is another significant factor, as high-performance materials like aerogels can be expensive. Additionally, regulatory standards and safety requirements add complexity to the design process. This section discusses these challenges in detail, offering insights into how engineers and manufacturers are addressing them through innovation and collaboration.

Innovations in Thermal Insulation Technology

The field of thermal insulation is constantly evolving, driven by the need for more efficient and sustainable solutions. Recent developments include the creation of nanocomposite materials, which mix the qualities of conventional insulation with improved thermal and mechanical performance. Smart insulation systems, equipped with sensors and adaptive materials, can dynamically adjust to temperature changes, improving efficiency.

Another promising area is the use of bio-based materials, which offer eco-friendly alternatives to synthetic insulation. Researchers are also exploring the integration of insulation with energy harvesting technologies, where waste heat is converted into usable energy. This section highlights cutting-edge advancements and their potential to revolutionize thermal insulation in battery compartments.

Real-World Applications of Thermal Insulation in Battery Compartments

Thermal insulation is a critical component in various real-world applications, from electric vehicles to grid-scale energy storage systems. In EVs, insulation ensures that batteries perform optimally in diverse climates, enhancing range and reliability. In renewable energy systems, insulation helps maintain the efficiency of battery banks used to store solar or wind energy.

Industrial applications, such as backup power systems and portable electronics, also benefit from effective thermal insulation. Case studies from leading manufacturers and research institutions provide valuable insights into how insulation technologies are implemented in practice. This section explores these applications, demonstrating the tangible impact of thermal insulation on performance and safety.

Future Trends in Thermal Insulation for Battery Compartments

As technology continues to advance, the future of thermal insulation for battery compartments looks promising. Emerging trends include the development of self-healing materials, which can repair damage caused by wear and tear, and the use of artificial intelligence to optimize insulation design. The growing emphasis on sustainability is also driving research into recyclable and biodegradable insulation materials.

Additionally, the integration of insulation with other battery management systems, such as thermal runaway prevention and state-of-charge monitoring, is expected to become more prevalent. This section explores these trends, offering a glimpse into the future of thermal insulation and its role in shaping the next generation of battery technology.